Saturday, July 27, 2024

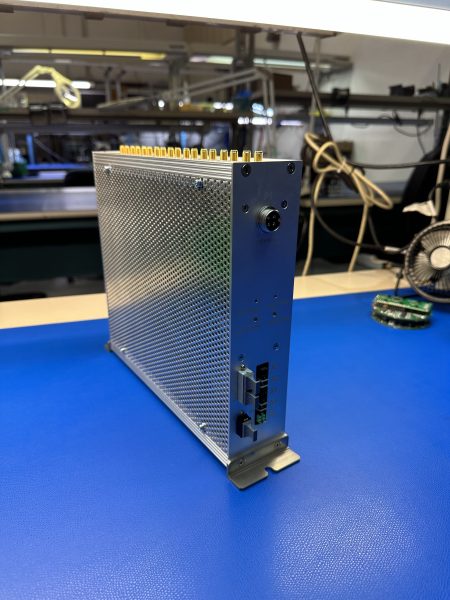

Marina, California – This past week, Indtec delivered our first turnkey image acquisition box build assembly for a global leader in the semiconductor equipment industry. This project allowed us to demonstrate the full range of our capabilities, from expedited turnkey procurement, to complex PCB assembly, in-house cable assembly, electromechanical integration; installing heat sinks, cooling fans, and fiber optic cable assemblies; as well as developing internal 3D-2D build instructions using SOLIDWORKS.

Establishing the Relationship

The relationship began with a call from a potential new customer who had visited our website in late 2023. We set up an initial meeting at Indtec, giving a tour of our facility and an overview of our management and operational processes. The customer’s project lead returned a few months later with his supervisor, and later again with his company’s CEO, to meet personally with Indtec management and discuss the basis of working together and establishing a relationship.

This project was an opportunity for Indtec to establish a new customer relationship and demonstrate the breadth of our capabilities, while delivering on-schedule with high quality standards. We used the customer’s new product development files and converted them into finished assemblies in less than two months (including time for procuring and receiving thousands of unique and sometimes hard-to-find board-level components). Undertaking this project required constant communication with the customer’s project lead to resolve various design related issues and procurement challenges. Our responsiveness and accessibility set us apart from the competition. The customer was very pleased with how quickly we identified issues, responded to communications, and adapted to changes in the build set to meet the end-customer’s demands.

Sourcing Materials

Once we received the customer’s purchase order, Indtec went to work, procuring all of the items in the bill of materials. Ordinarily, we would create internal part numbers, based on our internal part numbering system, in order to get the full use of common components, which we might already have in stock (thus reducing cost and procurement wait times). However, since this build required an especially aggressive schedule, we could not afford to lose valuable time assigning our internal part numbers to each component, so we had to order everything in the BOM, with enough excess material to cover any losses from pick-and-place feeding or assembly damage. In some cases for passive components, we were able to use capacitors and resistors available from our inventory.

During the procurement phase, we identified several challenges with unavailable / out-of-stock components. We used all of the methods and resources at our disposal, including escalating issues with supplier management and compressing lead times, navigating new tariff rules with distributors, conferring with the customer and agreeing on select alternate parts and sources of supply, and tracking down some customer-furnished items in other countries, which were otherwise unavailable on the open market. Due to this hands-on approach, we were able to reduce the lead time by half, while meeting the customer’s delivery expectations.

Documentation, Programming, and Setup

New Product Introduction (NPI) builds often require a certain level of manufacturing experience and expertise to turn raw design files into finished assemblies. This project was no different. The PCB design files did not include fab drawings. The customer specs called out a specialty prepreg material unavailable in the United States. Indtec’s technical staff worked with the customer to identify an equivalent PCB material from a U.S. based vendor, and we worked through all of the parameters needed to get bare PCBs that conformed to the customer’s requirements within a week from ordering.

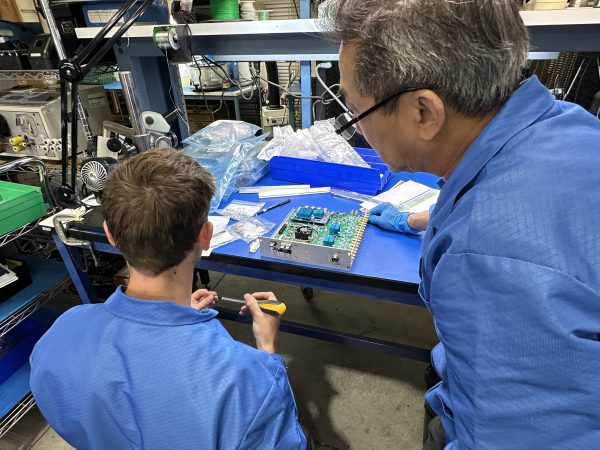

Indtec technical staff met with the customer at their location in San Jose, and we evaluated a previous prototype, taking photographs and notes, in order to assist in our own development build. These photographs and notes proved to be crucial when identifying cable-connector pin-outs and polarity issues, which we were later able to reference in our own assembly operations.

For the cable assemblies, the customer provided block diagrams and bills of material, which we converted into workable assembly aids and visual work instructions. For the final assembly / box-build stage, the customer provided a 3D model in SOLIDWORKS, but no drawings. Indtec created our own sub-assembly stages from the SOLIDWORKS files, and we created our own 2D drawings and assembly instructions.

The box build assembly included 3 printed circuit assemblies (PCAs): a challenging main digital board assembly, a daughter board assembly, and a power management board assembly. The main digital board consisted of more than a thousand components on both sides, including multiple FPGAs, various surface mount components of all sizes, and more than a dozen RF connectors and through-hole connectors that required hand solder. The main board required a full week of programming and setup, and another week of production activities, moving across every station in the factory. The daughter board and power management board assemblies were much more straight-forward, and required more normal levels of engineering review, documentation, programming, and setup.

Managing the Delivery Schedule and Expectations

Throughout the project, the customer was under pressure to meet an expedited delivery schedule from their end-customer. The asymmetry in organizational size from a large international end-customer, to a smaller global engineering firm, to Indtec (a local contract manufacturer in California), presented an opportunity and a challenge for Indtec, in terms of being small and nimble enough to move quickly, while having the expertise and management background necessary to work with larger, globally connected, customers.

Invariably, issues came up. Some cable components were not in the BOM, and required Next Day Air purchasing. Polarities and pin-outs needed to be checked. A ferrite ring was not large enough to allow two loops per wire – would one loop work? Throughout the course of the project, Indtec updated the customer project lead, and we received very quick responses on each issue, enabling us to stay on track and deliver on-schedule.

Building on this Experience

In large part, success in manufacturing is about continuously developing and maintaining institutional knowledge despite frequent change. Products change; manufacturing technologies, materials, and processes change; quality standards and customer requirements change. Organizations and people change. Great organizations have people who embrace change and learn how to do things better as things change. They maintain knowledge by developing and documenting procedures based on that learning, and they train others in the organization to put the knowledge to use.

This image acquisition box build assembly has been a positive learning experience for Indtec. It has been the most complicated box build that we have done in recent memory. The project has enabled us to use all of our capabilities, and provide personalized value-added services to a new customer. Based on this experience, we are confident that we will do even better the next time that we are called to build something new, something challenging, something exciting even.