OFFERING A FULL SPECTRUM OF PRODUCTION-INTEGRATED TURNKEY/CONSIGNMENT SERVICES

Turnkey Manufacturing

INDTEC offers comprehensive turnkey manufacturing services in California where we handle everything from procurement to assembly. This service allows our clients across various industries to focus on their core business while we manage the procurement and manufacturing process.

Initial Consultation and Quote

Tooling Design and Engineering Review

Procurement

We source components from OEMs, franchised distributors, and trusted suppliers. For aerospace and defense customers, we maintain appropriate US-based sources of supply.

Assembly

Testing and Quality Control

We perform visual inspection to IPC standards, and for more frequently ordered assemblies we perform automated optical inspection (AOI) as well as x-ray inspection for BGAs and various large ICs and connectors. For customers who arrange for acceptance testing at INDTEC, we use customer-provided test procedures, test programs, and test equipment for functional acceptance testing and test reporting.

Delivery

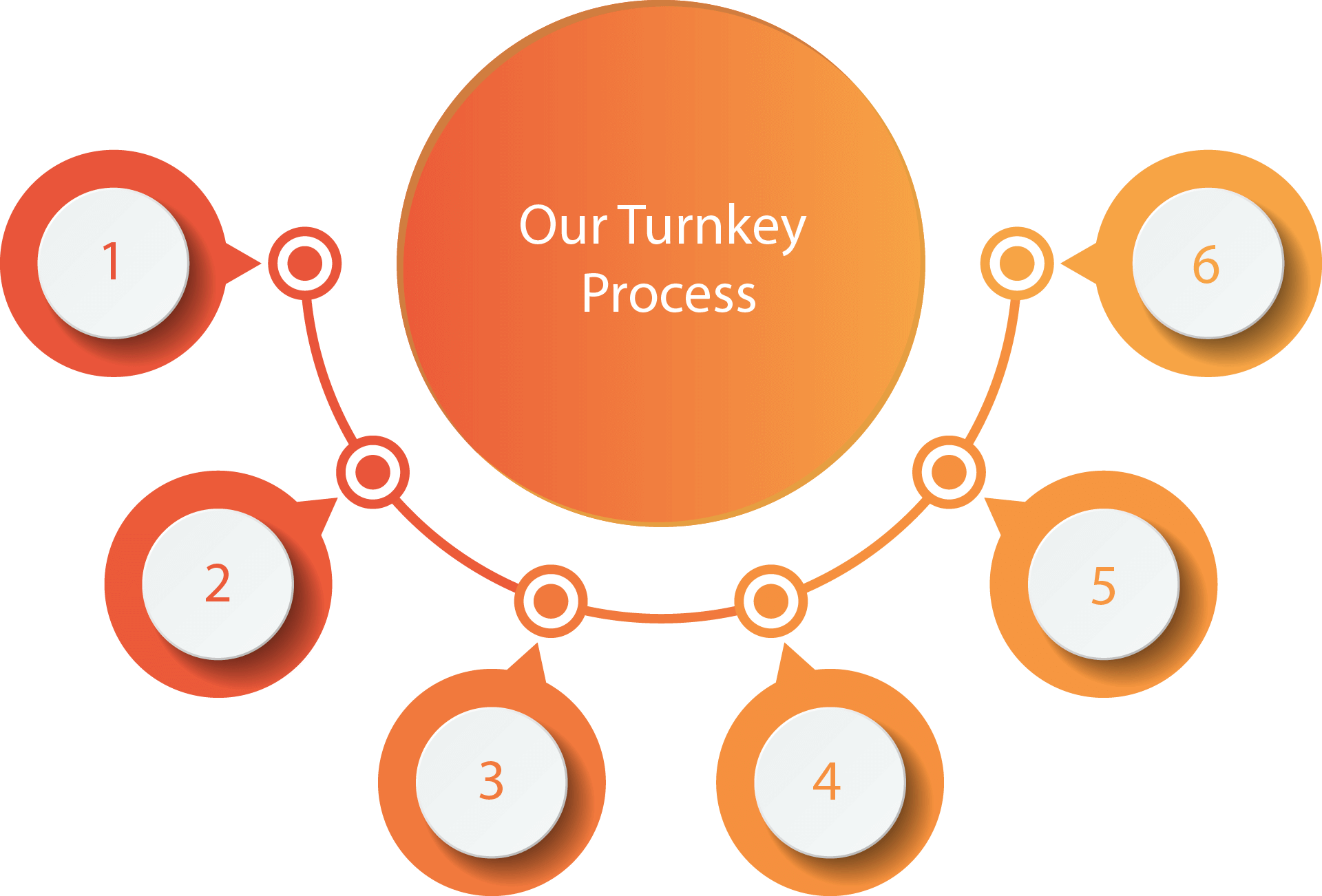

Turnkey Manufacturing Services

INDTEC offers comprehensive turnkey manufacturing services in California where we handle everything from procurement to assembly.

This service allows our clients across various industries to focus on their core business while we manage the procurement and manufacturing process.

1 Initial Consultation and Quote

2 Tooling Design and Engineering Review

3 Procurement

We source components from OEMS, franchised distributors, and trusted suppliers.

4 Assembly

Our skilled technicians assemble the products in accordance with the BOM, assembly drawings, and relevant specifications and standards.

6 Delivery

5 Testing and Quality Control

We perform visual inspection to IPC standards, and for more frequently ordered assemblies we perform automated optical inspection (AOI) as well as x-ray inspection for BGAs and various large ICs and connectors. For customers who arrange for acceptance testing at INDTEC, we use customer-provided test procedures, test programs, and test equipment for functional acceptance testing and test reporting.

Turnkey Manufacturing Benefits

Our Consigned Manufacturing Process

For clients who prefer to supply their own materials, INDTEC provides consigned manufacturing services. We assemble and inspect your products, ensuring they meet your design requirements. This model allows clients to maintain control over the sourcing of materials while benefiting from our expert assembly, inspection, and testing services (if applicable).

We perform kit audit to ensure that we have all customer-provided parts on hand in production ready quantities. Customers need to provide machine-ready reels or tape with sufficient quantity of excess parts to act as a leader through the machine. All excess parts are returned to the customer, or maintained on hand at INDTEC, depending on customer preference.

We perform visual inspection to IPC standards, and for more frequently ordered assemblies we perform automated optical inspection (AOI) as well as x-ray inspection for BGAs and various large ICs and connectors. For customers who arrange for acceptance testing at INDTEC, we use customer-provided test procedures, test programs, and test equipment for functional acceptance testing and test reporting.

COnsignment Manufacturing Benefits

Customers who maintain their own inventory eliminate the need for INDTEC to source parts, significantly reducing lead times for finished products.