Just like humans perform best within a comfortable temperature range, electronic components also thrive when kept within specific thermal limits. When these limits are exceeded, the performance and reliability of these components can be compromised, much like how excessive heat impacts human productivity. This is where heat sinks become a critical solution, offering efficient thermal management to maintain optimal operating conditions for electronic devices.

Understanding the Role of Heat Sinks

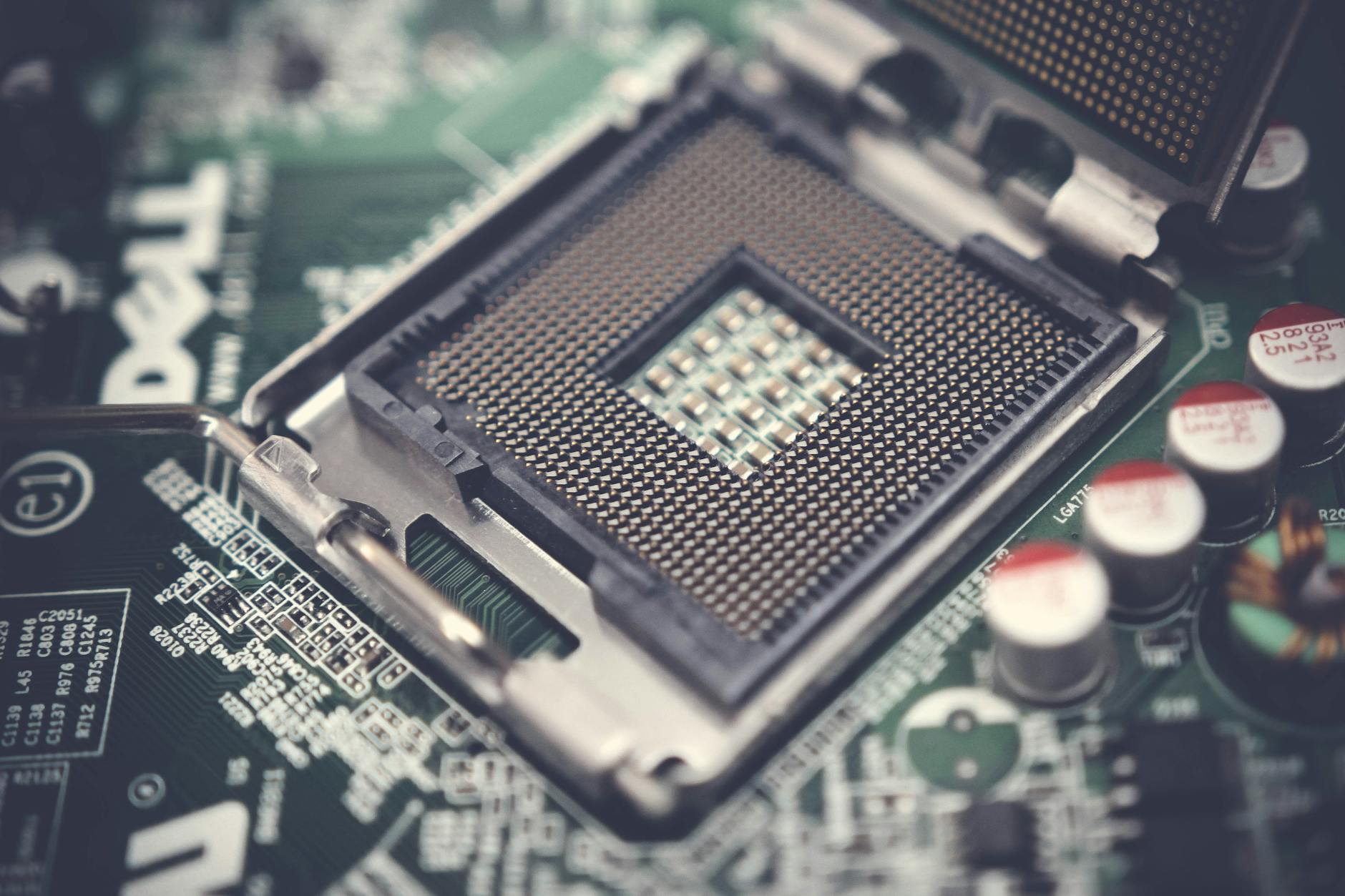

Heat sinks are passive devices designed to dissipate the excess heat generated by various electronic components, including CPUs, GPUs, and other integrated circuits. Their primary function is to transfer heat away from the components, preventing potential overheating and ensuring they operate within safe temperature thresholds.

Constructed from thermally conductive materials such as aluminum or copper, heat sinks are designed to maximize heat transfer. Many heat sinks feature fins or other structures that increase the surface area available for cooling, allowing the heat to dissipate more efficiently into the surrounding air. Some designs even incorporate fans or other active cooling mechanisms to further enhance heat removal.

How Heat Sinks Work

The process by which heat sinks manage temperature can be broken down into four key steps:

- Direct Contact: The base of the heat sink is placed in direct contact with the heat-generating component, such as a processor or power transistor.

- Heat Transfer: As the component heats up, thermal energy is conducted from the component to the heat sink’s base.

- Heat Dissipation: The heat is then spread across the fins or surface extensions of the heat sink, increasing the surface area exposed to air. This allows the heat to dissipate into the surrounding environment through natural convection.

- Optional Cooling Fan: In some setups, a fan may be added to actively enhance the airflow, accelerating the cooling process. This is common in high-performance systems like desktop computers and gaming consoles.

By managing the heat produced during operation, heat sinks are crucial in preventing overheating, maintaining system stability, and protecting components from potential damage.

The Importance of Heat Sinks in Electronic Systems

Heat sinks are essential to electronic circuits for several key reasons:

- Efficient Heat Dissipation: Power components such as voltage regulators, transistors, and integrated circuits generate heat during use. Without proper heat dissipation, components can overheat, leading to failure. Heat sinks effectively draw heat away, maintaining a stable temperature.

- Temperature Control: Electronic components often have strict operating temperature ranges. Heat sinks help regulate these temperatures, ensuring reliable performance even under high workloads.

- Prolonged Lifespan: Excessive heat accelerates the wear and tear on electronic components, shortening their lifespan. By keeping temperatures in check, heat sinks contribute to the durability of the components and the overall system.

- Optimized Performance: Certain components, especially power-hungry ones, can exhibit decreased performance if they overheat. A well-designed heat sink ensures these components function at their peak, improving the overall performance and stability of the device.

- Reduced Thermal Stress: Frequent temperature changes, known as thermal cycling, can put stress on solder joints and PCB traces. Heat sinks mitigate this issue by maintaining more stable operating temperatures.

- Compact Design: Heat sinks enable the creation of more compact devices by replacing the need for bulkier, traditional cooling methods, making them ideal for applications with limited space.

Key Features of a Heat Sink

A heat sink’s effectiveness depends on several critical elements:

- Base: This part of the heat sink makes direct contact with the heat-generating component and plays a crucial role in efficient heat transfer.

- Material: Most heat sinks are made from materials with high thermal conductivity, such as aluminum or copper, to ensure quick and effective heat dissipation.

- Fins or Ridges: These features increase the surface area of the heat sink, enabling better heat dissipation by allowing more contact with the surrounding air.

- Heat Pipes (Optional): In more advanced designs, heat pipes can be incorporated to transport heat more efficiently from the component to the fins.

- Thermal Interface Material (TIM): A thermal paste or pad is often applied between the base of the heat sink and the component to fill microscopic gaps, improving heat transfer between surfaces.

Materials Used in Heat Sink Manufacturing

The materials used in heat sinks are chosen for their high thermal conductivity, ensuring efficient heat transfer from the components. Some of the most commonly used materials include:

- Aluminum: Known for its excellent balance between cost, weight, and thermal conductivity, aluminum is widely used in heat sink manufacturing.

- Copper: With superior thermal conductivity compared to aluminum, copper is often used in applications requiring maximum heat dissipation. However, it is heavier and more expensive.

- Aluminum and Copper Alloys: These alloys can offer a blend of thermal performance and mechanical strength, making them ideal for specific applications.

- Graphite and Graphene: These materials, known for their exceptional thermal conductivity, are gaining attention for high-performance applications where efficient heat management is critical.

Types of Heat Sinks for Different Applications

There are various types of heat sinks, each tailored to specific electronic devices and applications:

- Finned Heat Sinks: The most common type, featuring a base with fins to increase surface area and improve heat dissipation.

- Plate or Flat Heat Sinks: These are used for components with large surface areas and are often found in power modules.

- Clip-On Heat Sinks: Easily attached using clips or springs, they are commonly used in CPUs and GPUs.

- Soldered or Adhesive Heat Sinks: These are used for surface-mount components, providing excellent thermal contact.

- Heat Pipe Heat Sinks: These include heat pipes for enhanced heat transfer and are used in more advanced systems.

- Liquid Cooling Systems: These use a coolant to remove heat from components and are found in high-performance systems like gaming computers.

- Extruded Heat Sinks: Manufactured by extruding materials into specific shapes, they are used in a wide range of applications due to their cost-effectiveness.

- Folded Fin and Pin Fin Heat Sinks: Designed for high-density cooling, these are used in applications where space is limited but efficient heat management is necessary.

By incorporating the right type of heat sink, electronic systems can maintain optimal temperature control, ensuring stable performance and long-term reliability.

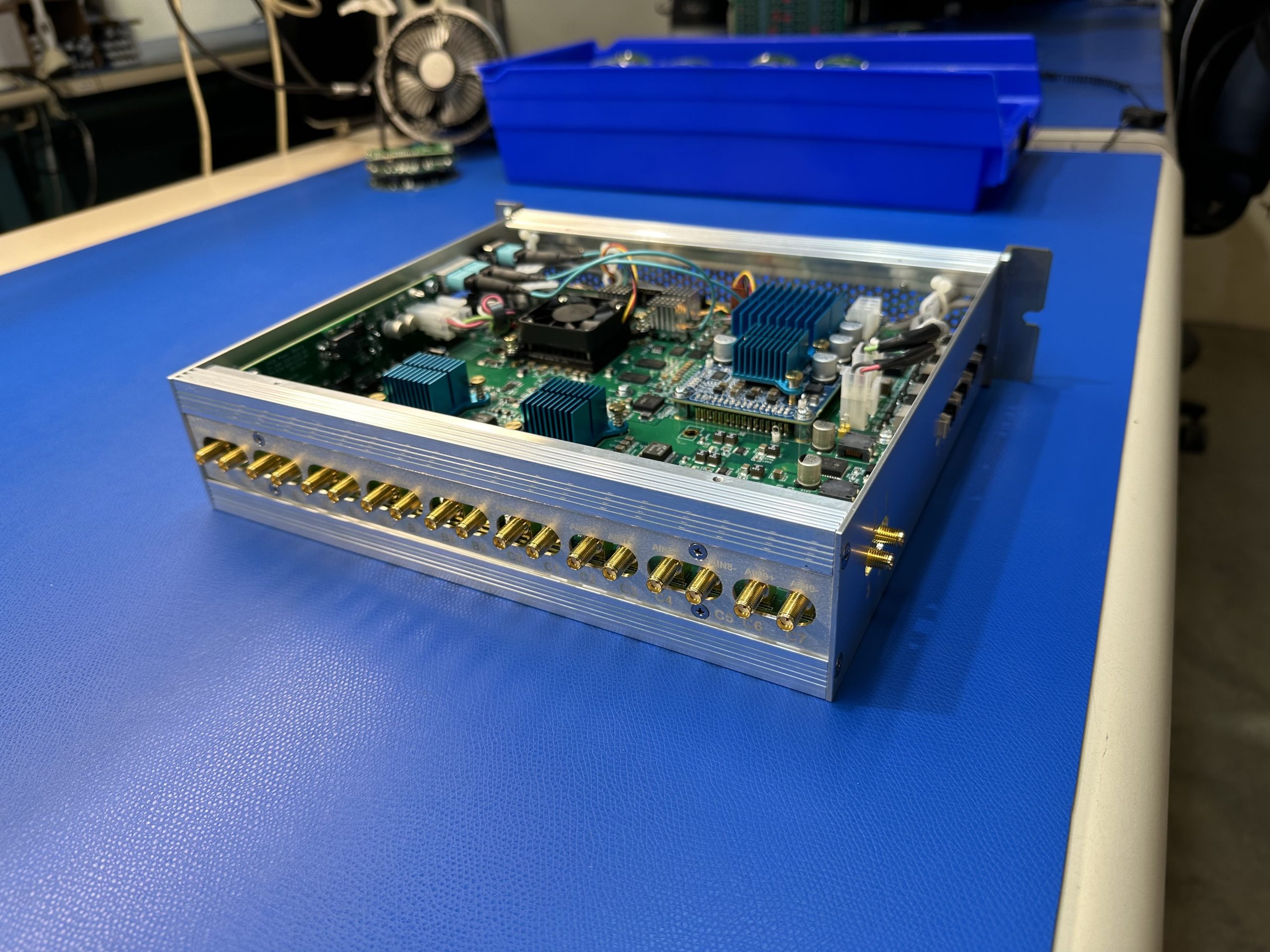

Unlock Superior PCB Assembly with Indtec

At Indtec, we specialize in delivering high-quality PCB assembly solutions tailored to your unique project needs. Whether you require prototypes or full-scale production, our experienced team uses cutting-edge techniques and materials to ensure precision, reliability, and optimal performance in every assembly.