Indtec capabilities include:

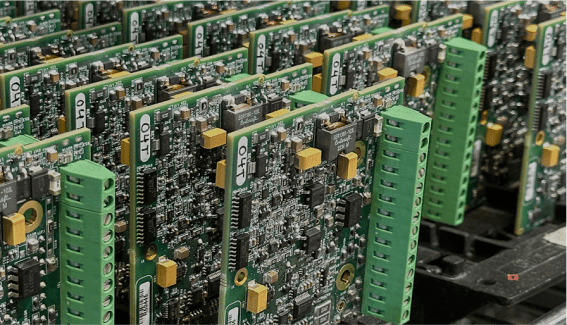

PRINTED CIRCUIT BOARD ASSEMBLY SERVICES

Indtec delivers both consignment and full service / turn-key printed circuit board assemblies (PCBA).

We have equipment and processes dedicated to both tin-lead and lead-free (Pb-free) solder operations. Indtec operates three Surface Mount Technologies (SMT) production lines, with automated solder stencil printers, pick and place machines, reflow ovens, cleaning systems, and automated optical inspection (AOI). We perform 100% X-Ray inspection for BGA components.

Our Capabilities

- Surface Mount Technology (SMT): Our SMT capabilities include high-speed placement of components down to 0201 package size, fine pitch components, and double-sided assemblies.

- Through-Hole Assembly: We perform through-hole assembly for legacy components and other components that require strong mechanical bonds.

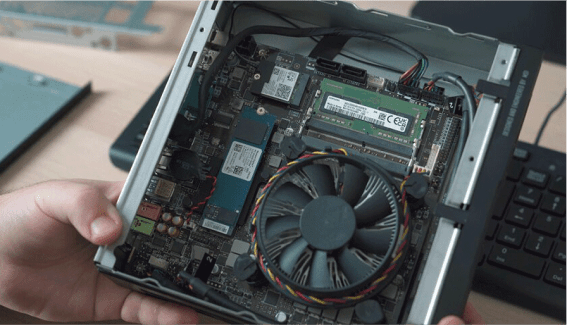

Electromechanical Assemblies & Box Builds

Our experienced technicians can perform a variety of integration-related services, from sensor-board connections, to motor and fan assemblies, or full-scale box builds.

Indtec provides comprehensive electromechanical assembly services, creating complex assemblies that include circuit boards, cables, sensors, and more. Our electromechanical assemblies, also known as box builds, are built to meet the unique standards of each client.

Our Capabilities

- Box Builds: We offer complete system integration and box build services.

- Sensor Integration: Our electromechanical assemblies often include sensors for various applications.

- Motor and Fan Integration: We can integrate motors, fans, and other mechanical components into our assemblies.

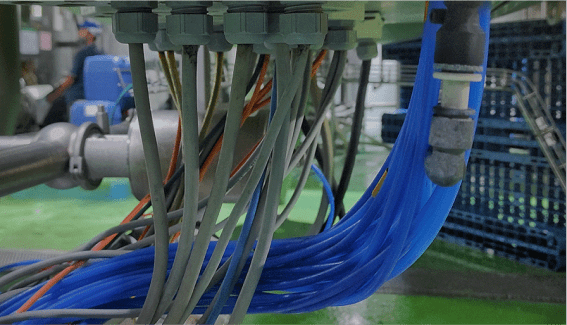

Custom Cable

Assemblies

Indtec has the capability to build cable and wire harness assemblies, for either high volume production needs, or custom solutions for test equipment, instrumentation, or prototype / development builds for new product introduction (NPI).

We offer high-tech instrumentation and test cables for specialized applications. Our custom cable assemblies are built to meet the unique requirements of each client, ensuring high quality and reliability.

Our Capabilities

- Instrumentation Cables: We manufacture high-quality instrumentation cables for a variety of applications.

- Test Cables: Our test cables are assembled to meet the rigorous demands of testing and validation processes.

- Prototype Cables: We offer prototype cables for new product development and testing.